Smart Gun Control System 2000 — SGCS2000 (Revision 1.2)

Smart Gun Control System 2000 is a system of control and synchronization by GPS Time of air-emitters arrays.

The developed industrial hardware-software complex provides control, synchronization and monitoring of pneumatic emitters during seismic exploration and engineering-geophysical surveys.

The system allows controlling up to 128 pneumatic emitters of different types (Bolt, Sleeve Gun, GI Gun and others), and is also capable of monitoring and recording data from near-field hydrophones from 128 and more sensors with a maximum sampling rate of 0.05 ms and accurate time reference.

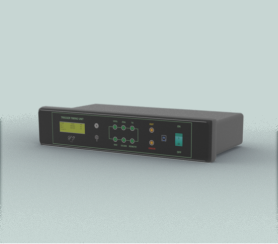

The SGCS 2000 complex consists of: a host server (Host PC), a start and time synchronization unit (TTU), and a number of scalable control units (SGCS2000), each of which can control up to 8 pneumatic transmitters.

SGCS2000 control units support the ability to generate trigger pulses to trigger individual pneumatic emitters at a specific programmable design time.

Modern high-tech industrial analog and digital circuits — allow recording and analysis of data from sensors and hydrophones of the near zone using 20-24-bit high-speed ADCs of SAR types with extremely high sampling rates — 0.03 ms., which provides increased sensitivity and accuracy when using «smart» algorithm of automatic synchronization.